Capabilities

Precision machining, on demand.

Precision Machining

We have the ability to handle multiple materials including, but not limited to, bar stock, billet, castings and plastics.

Castings

We Know Castings. Our sister company, UniPunch Products, makes c-frame press tooling from ductile iron castings. We have many years of experience machining castings with tight tolerances.

Steel Fabrication

We offer a wide range of structural steel products from simple staircases and platforms to complex catwalks and mezzanines.

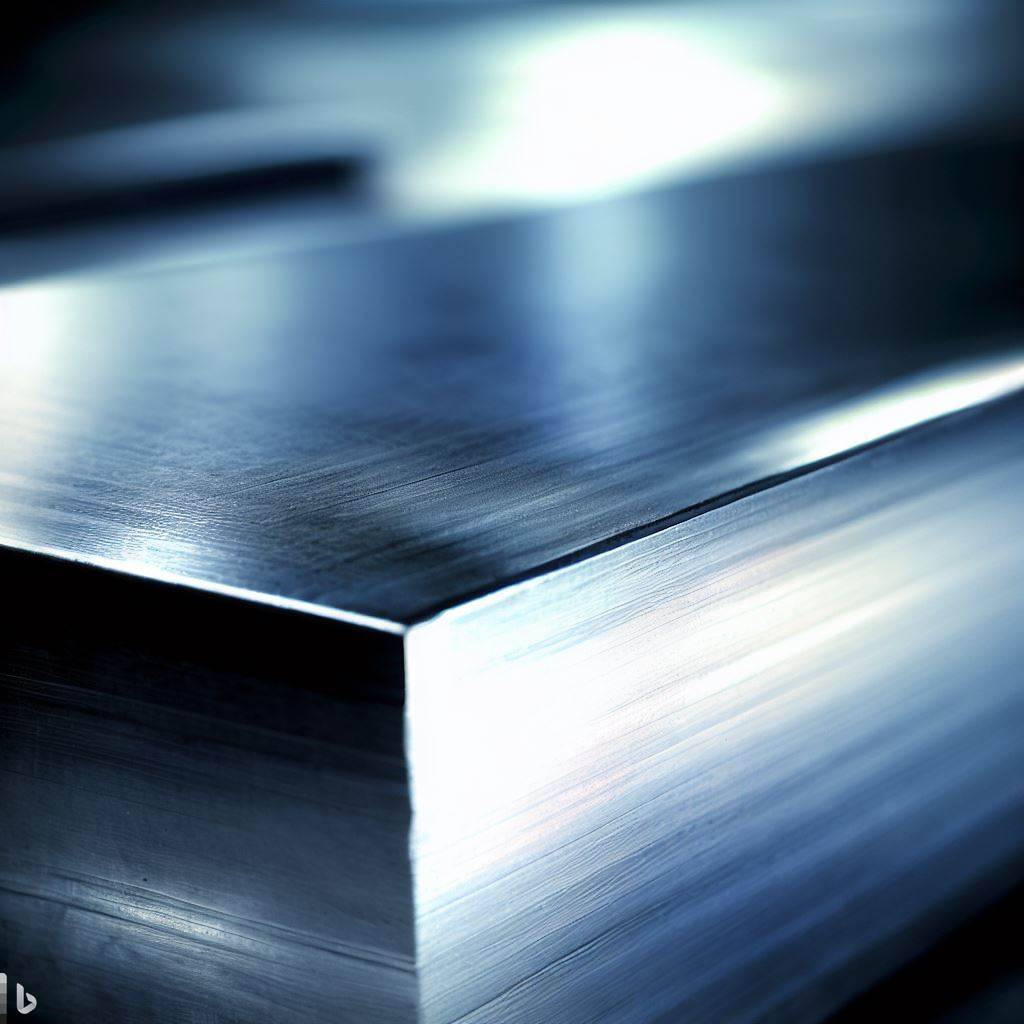

Billet

We machine semi-finished casting products, including billet.

Plastics

We machine plastic and composite parts. Plastic material includes white derlin, black derlin, peek, and teflon.

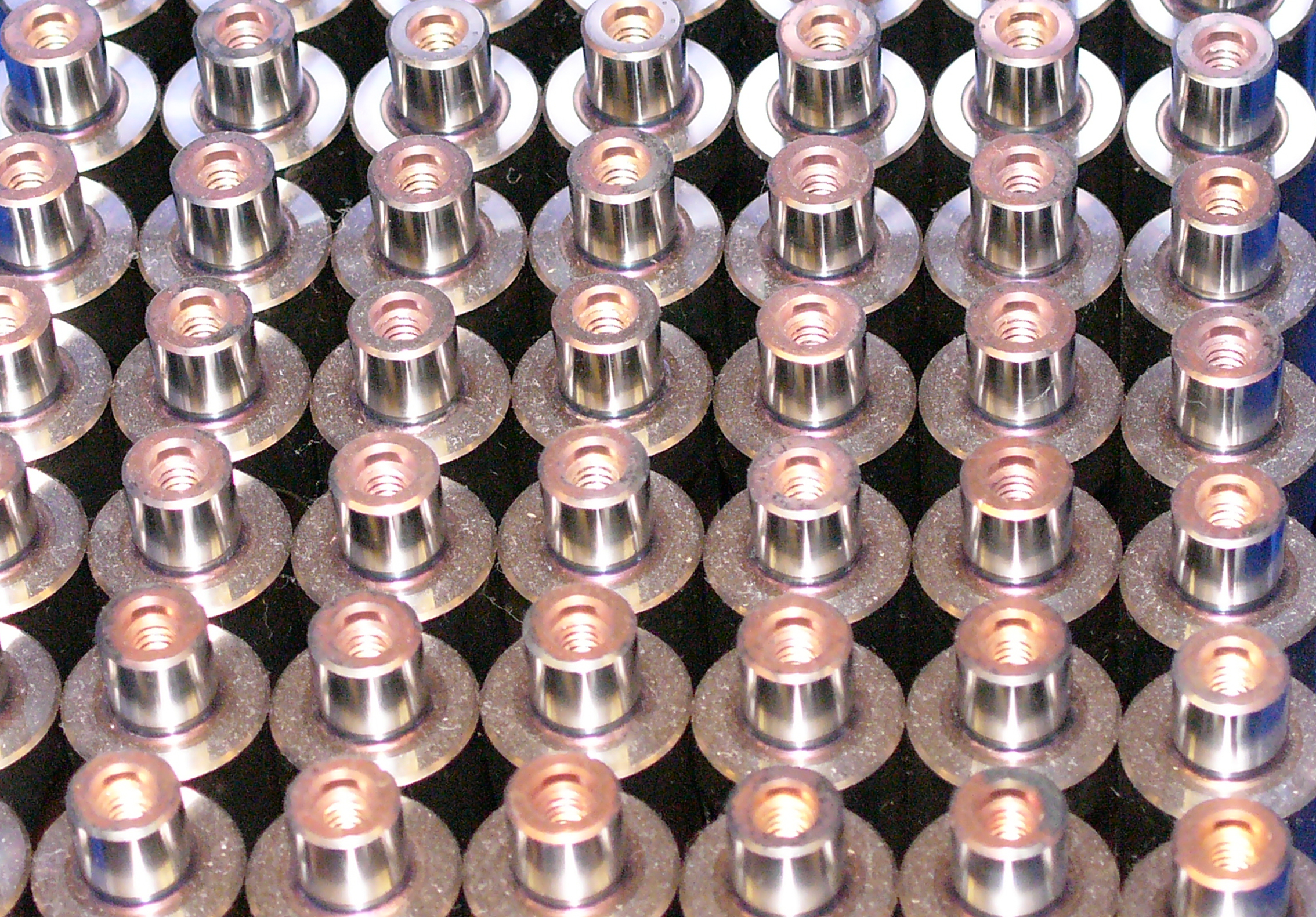

Bar Stock

We process bar stock in up to 24 ft. lengths.

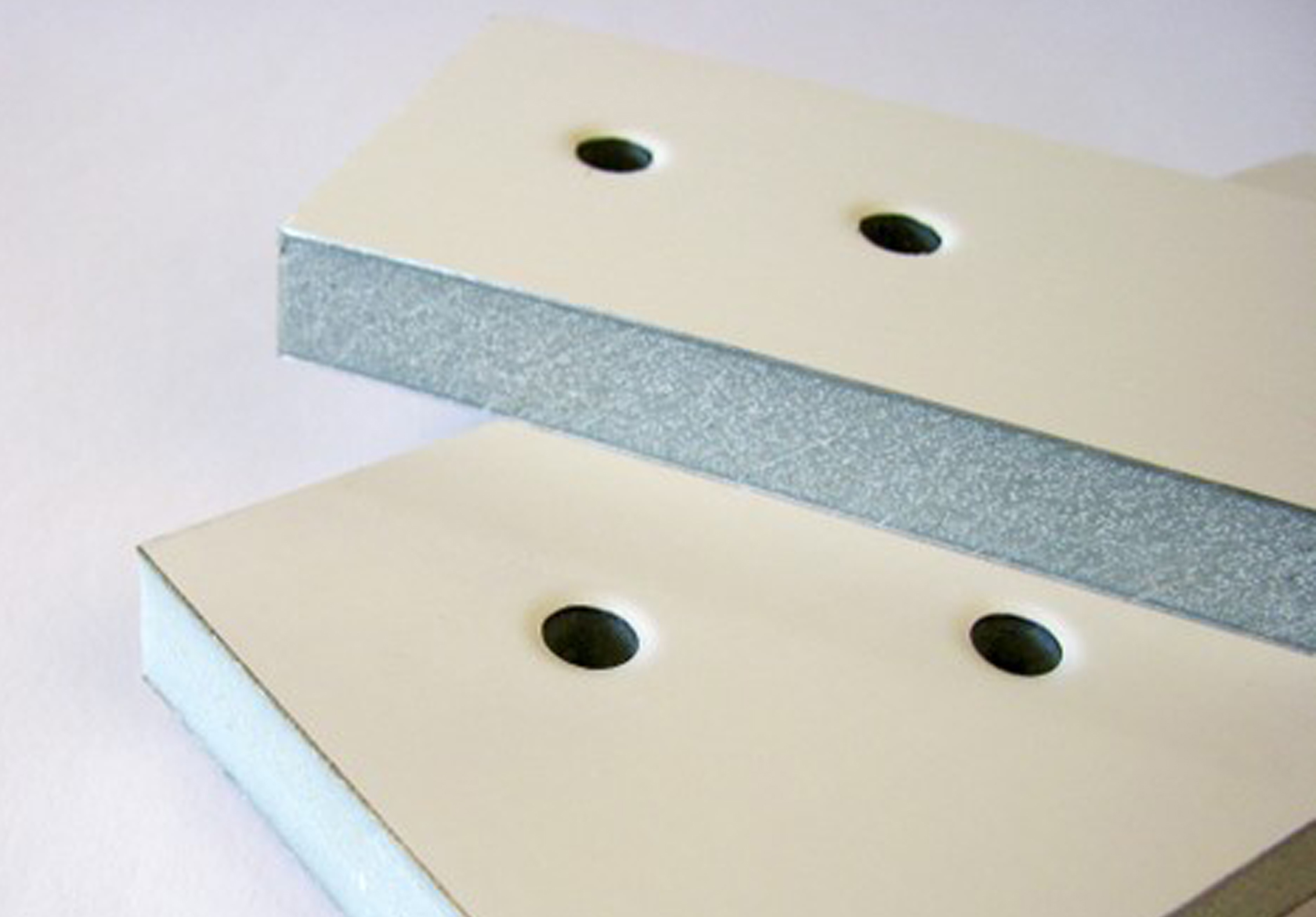

Fiberglass

We machine fiberglass g7 and g10.

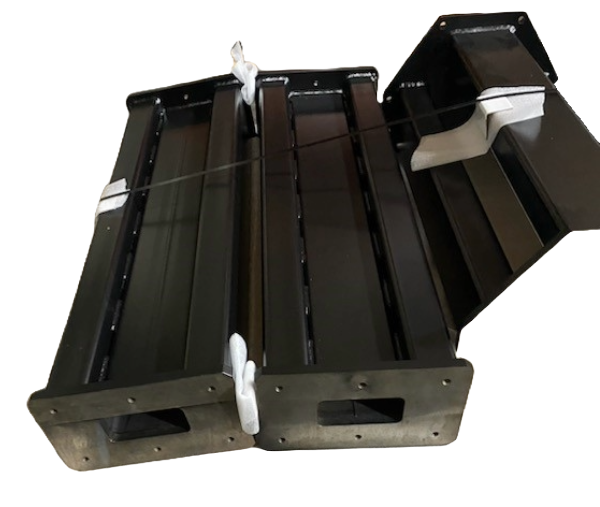

Weldments

Miscellaneous

We machine aluminum with rubber bonded to it.

Enclosures

We manufacture simple and complex mechanical and electrical enclosures.